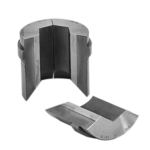

The Style “S” master collets and pads overcome all the problems associated with master collets. When loading bars, the rugged shoulder of the pad locates against the front of the groove in the master collet. There are no set screws or clamps to be damaged or loosened. When a part is machined, the working forces are against the rear shoulder of the pad which is located against the rear shoulder of the groove in the master collet. Again, there are no screws or clamps to wear or break. The clamp which holds the pads captivated in the collet literally floats longitudinally, assuring that there is never any pressure on the clamp. There are no holes in the OD of the master collet, or on the ID of the pads, resulting in maximum bearing on the workpiece and the spindle collet seat. When Style “S” collets are used, there will never be high spots on the spindle collet seat caused by the master collet and pad design. When selecting master collets from this catalog, remember the Style “S” design has been in existence for over 50 years and is the preferred system.

- Maximum bearing surface between the spindle and head angle. Because there are no holes or slots in the head angle of the collet, uneven wear of the spindle will not result from continuous use. There are no threaded holes in the collet to be stripped or damaged.

- Ease of Use. Since the pads are interchangeable without removing the master collet from the spindle, collets do not have to be removed from the machine when changing the bar stock size. Independent clamps slide freely in and out of the master collet so they can be removed with ease.

- Secure Pad Installation. The unique dovetail anchor system securely holds pads in place while feeding bar stock. This design places the bar thrust on the shoulder of the pad. There is no pressure on the clamp assembly because it is ideally positioned between the pad shoulder and the recess of the collet. The pads cannot dislodge under normal use.