Machine Inventory Sale

Exclusive, limited-time offers on precision CNC turning centers, milling machines, grinders, multifunction turning/grinding machines, and more. Act fast: all machines are in-stock and ready to ship!

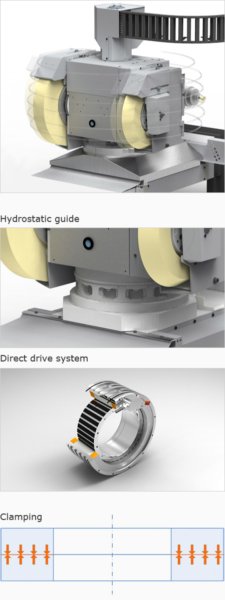

KELLENBERGER launches a new, extremely accurate B-axis generation with a concept that is unique for universal cylindrical grinding machines. The full-fledged NC-axis with pre-tensioned hydrostatic guide and a direct drive increases the potential of universal cylindrical grinding.

KEL-VARIA and KEL-VERA with new B-axis

Over 20 years of experience in the development and manufacture of longitudinal hydrostatic guides has gone into the new KELLENBERGER hydrostatic B-axis. This adds a feature with a promising future to the model series KEL-VARIA and KEL-VERA.

The pre-tensioned hydrostatics are the basis for higher accuracy and better surface quality. Steps of 0.0001 degrees can be traveled with no problem, and give the machine its “measuring machine” standard of precision. The positioning accuracy of less than one arc second allows positioning of grinding wheels that is comparable to the linear X and Z axes.

The high rigidity means that complete processing jobs can be optimized, and productivity raised. The high degree of positioning accuracy improves dimensional accuracy, especially in cases where dressing cannot be carried out after swiveling, such as when using e.g. CBN or diamond grinding wheels.

The direct drive is wear-free and allows high travel speeds. Tool change times are radically reduced, which also minimizes non-productive time. The drive system is even open to future application possibilities such as e.g. in the area of simultaneous processing.

Technical data

Rotational speed: 30 min.-1 (1 sec. / 180°)

Smallest position step: 0.0001°

Resolution: 0,00002°

Positioning accuracy: < 1“

Clamping: Working in either clamped or unclamped condition

Swiveling range: 240°

Construction

Hydrostatic guide

The hydrostatic guide has excellent damping and has a decisive influence on surface quality.

The low-friction guide facilitates the highest precision.

Rigidity is higher than comparable roller guides, and leads to an improvement in productivity.

Process reliability is guaranteed for the entire service life, thanks to the consistent characteristics.

The wear-free guide increases operational dependability and reduces maintenance costs.

Direct drive system

The water-cooled high-torque motor guarantees a high level of torque.

A high resolution rotary encoder guarantees the highest degree of accuracy. The rotary encoder is integrated in the absolute measuring system of the machine and requires no referencing.

The direct drive and the low-friction guide mean that the B-axis has no play in the drive train, and together with the high rigidity, the drives can be more dynamically controlled.

The absence of wear guarantees good positioning characteristics for the entire service life.

Clamping

The B-axis can be clamped in any position without any deformation.

The large dimensions of the clamps guarantee high clamping moment.

Summary of new B-axis

In the new model, KELLENBERGER has succeeded in expanding to other axes the principle of hydrostatic guides. The positioning accuracy is comparable to a linear axis, so corrections can be made in very small increments. The new concept allows work to be done even without clamping, and is open to new working strategy options!

State-of-the-art engineering combined with fair conditions mean that the new B-axis provides the customer with competitive advantages and an economical and dependable solution for reliable production.

Visit us at EMO in hall 11, stand D60