User-friendly, ergonomic design

Simple operation via intuitive touchscreen interface

Technical highlights

- State-of-the-art Fanuc CNC system with 19″ touchscreen

- Guide with special coating for wear-free operation and perfect contour precision

- Temperature stability thanks to integrated cooling circuit

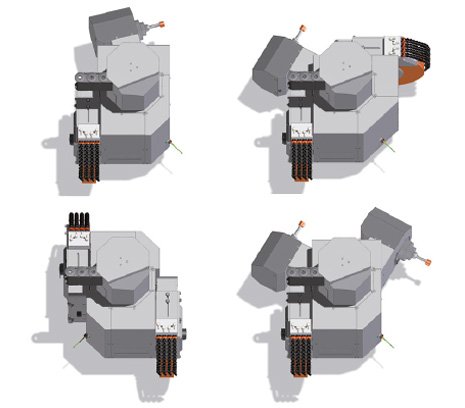

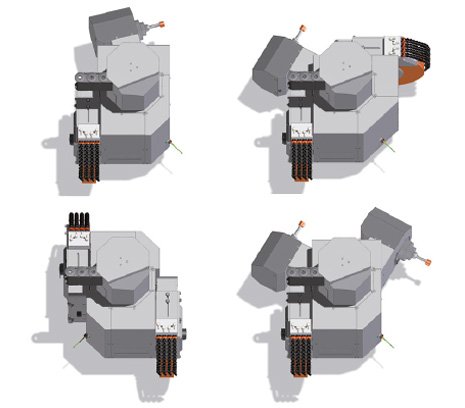

- Innovative compact wheelhead with 10 versions and 11.5 kW drive output

- Collision-free grinding configuration of 3 tool positions and one measuring position

- New measuring sensor configuration without tilting mechanism for increased measurement precision

- High dimensional precision for non-circular grinding thanks to direct drive at the workpiece

- Replacement of belt-driven internal grinding spindles with lower-cost motor spindles

- Large capacity with 200 mm centre height and 150 kg workpiece weight

- New dressing concept with optimised, generous stroke ratios

- Open system for automation, automatic door operator

- Integrated lifting system for changing grinding wheels and tailstock mounting

- Servicing-friendly machine design

Base

- FEM-optimised cast bed

- Optimised slideway on Z-axis

- Linear guide on X-axis

Modular wheelhead with high-precision B-axis

10 compact wheelhead versions for optimal machine design based on the parts to be processed. Diagonal configuration and new collision-free universal design with 500 mm grinding wheel diameter.

Workhead and tailstock

- Standard design with 100 kg workpiece weight

- Strengthened version with 150 kg

- High torque for non-circular grinding

- Synchronous tailstock including automatic fine adjustment for production applications

CNC control system with Fanuc 31i with 19″ touchscreen

- Comprehensive user support with revamped intuitive touchscreen control

- Redesigned cycle programming

- Workpiece-based graphic programming

- Integrated automatic calculation technology

Downloads