Machine Inventory Sale

Exclusive, limited-time offers on precision CNC turning centers, milling machines, grinders, multifunction turning/grinding machines, and more. Act fast: all machines are in-stock and ready to ship!

The multifunctional precision turning machine is designed to open up new industries

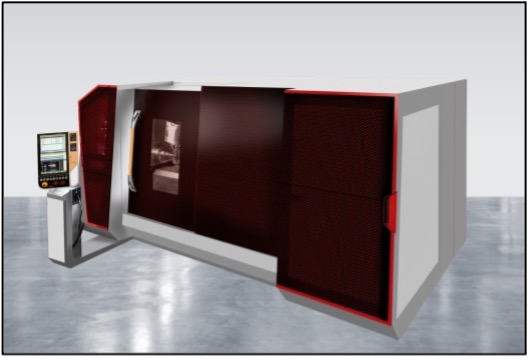

St. Georgen, Germany (February, 2022) – The horizontal precision turning machine “ARTERY” developed by WEISSER is characterized by compactness, highest precision and favorable costs. Thus, the company addresses new industries with high demands on workpiece precision and the need for precision turned parts. The focus lays on companies in mechanical engineering, medical technology and aerospace.

“The ‘ARTERY’ incorporates decades of experience from the automotive industry and in dealing with OEM manufacturers, who have high and ever-increasing demands for highest precision as well as process reliability,” says Daniel Setka, Head of Marketing J.G. WEISSER Söhne. “This know-how has been incorporated into the ARTERY, which we now intend to use to win additional customers from non-automotive sectors.”

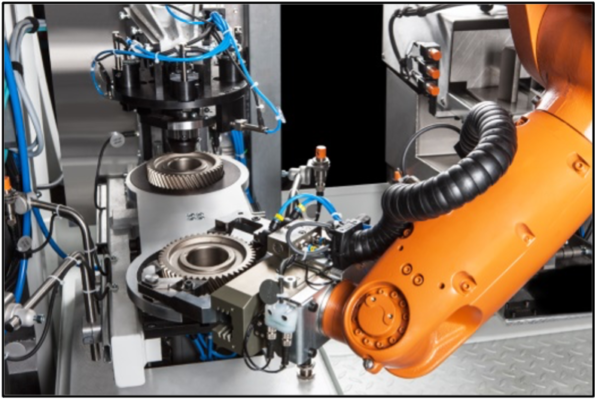

Various automation solutions can be additionally adapted to the ARTERY. Robot automation for example offer a highly flexible loading and unloading method for the machining center

Compact and precise

The ARTERY is characterized by functional design with utility effects and a vibration-optimized thermo-symmetrical design. The high vibration damping, flexibility and precision are important in all industries for which the ARTERY is of interest. Here, the concentricity of the main and counter spindle with 0.002 mm (on average) is convincing. Even in continuous operation, the ARTERY works precisely and with the highest spindle accuracy. The use of extremely rigid guides significantly reduces wear, which has a positive effect on maintenance and servicing costs.

The FEM (Finite Element Method) and topology-optimized machine columns and slide units ensure stability. The compact cartridge milling spindle (B axis) can be replaced in just a few steps and without the need for an electrician. Due to the particularly long Z-axis, the machine is therefore ideally suited for complete bar machining.

The ARTERY is the answer to a multifunctional high-performance machining center for turning operations or turn-mill complete machining in one or two setups.

The “direct-wall-concept” design allows the machine to be set up almost against the wall. This results in high productivity per unit area with unrestricted, excellent accessibility.

Three configurations for optimized usage

Three workspace configurations provide more flexibility and allow hard turning, milling, drilling, reaming and green turning, i.e. machining of molded parts manufactured by pressing and sintering (die pressing, metal injection molding). All three configurations enable economical and high-precision machining of various chuck and shaft parts. In addition to 6-sided complete machining, time-saving turning and milling from bar stock with a turning length of up to 1200 mm and a diameter of 65 mm is possible; this applies to all machine variants.

All three basic variants can be equipped and modified according to customer requirements. Thus, with the ARTERY, WEISSER offers the optimum equipment for every application.

About the company:

J.G. WEISSER Söhne, headquartered in St. Georgen, Germany, is a specialist for turning machining centers as well as innovative additive manufacturing and laser systems. The company has a worldwide presence with sales and service subsidiaries as well as commercial agencies. The largest customer industries are the automotive industry as well as the medical and aerospace industries. J.G. WEISSER has two additional business units. While JGWS focuses on innovative turning solutions, the WPT business unit contributes its expertise in additive manufacturing and laser processing. Both companies offer customized TURNKEY solutions. WMS offers complete machine overhauls and corresponding services. Since 2021, J.G. WEISSER Söhne is part of the US-based HARDINGE Group.

Editorial contact:

Daniel Setka

Head of Marketing

Tel. +49 7724 881- 435

daniel.setka@weisser-web.com

www.weisser-web.com

J.G. WEISSER SÖHNE GmbH & Co. KG

Johann-Georg-Weisser-Strasse 1

78112 St. Georgen