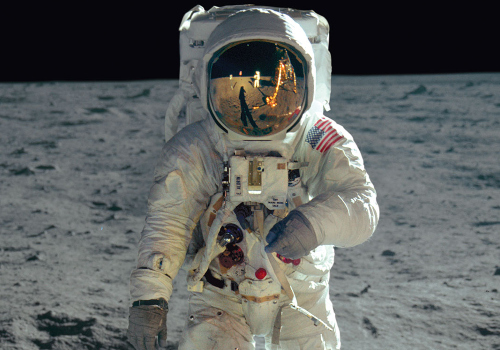

As the world celebrates the 50th anniversary of the 1969 Apollo 11 moon landing, it’s worth taking a look back at how dramatically the aerospace industry has changed since then. Space travel and exploration has been privatized. We now have several companies such as SpaceX, Blue Origin, Virgin Galactic and more, developing reusable space rockets and commercial space vehicles.

Aerospace manufacturing now includes aircraft, guided missiles, space vehicles, aircraft engines, propulsion units, and related parts.

Improvements in aerospace technology – from engine/wing design to power sources to lighter, stronger materials – have revolutionized air flight and space exploration. However, these valuable updates have created growing demands in aerospace manufacturing, especially for absolute adherence to specifications. There’s no room for error when even the tiniest imperfection can create catastrophic results.

Aerospace Industry’s Demand for Precision

One of the most regulated industries in the world, the aerospace and defense (A&D) manufacturing environment and processes are complex and diverse, mixing intricate and heavy-duty operations. To meet unique product requirements, suppliers may need accommodate large cumbersome parts and complex machining.

Typically, in A&D manufacturing, custom work is the norm. Many parts are engineered or manufactured to order, requiring specialized tooling and workholding solutions. Flexibility is another requirement, as engineering change notices will necessitate changes to product or component design, which can impact the sourcing of parts and subsequent manufacturing processes.

For example, the aerospace industry has advanced greatly in the design of the gas- powered turbine engines. Today’s manufacturers of jet engines demand very close tolerances, which in turn are dependent on precision forgings, castings and machinery from its suppliers. Not surprisingly, the quality and reliable sourcing of these critical components is vitally important, so suppliers face strict oversight and quality standards.

Workholding Requirements

To meet the precision demands of the industry, A&D suppliers need to have adequate workholding capabilities. The proper workholding solution can bring the highest level of precision to your machining operation or allow for the utmost in flexibility for accommodating multiple part configurations. Suppliers need to be able to securely clamp large parts, even when most of the material will be removed, and efficiently handle changeovers between part types or within part families as needed. Innovative solutions based on Forkardt’s broad experience in the workholding industry are what allow our engineers to optimize solutions to reduce set-up time while maintaining accurate workpiece placement.

While it may be tempting to apply a “one size fits all” approach using a simple 3-jaw chuck, it is vital to match the workholding solution with the product requirements. With the right workholding solutions, A&D manufacturers can reduce labor costs and necessary tool changes, as well as minimize idle spindle time in order to complete jobs faster. Choose incorrectly, and you’ll end up wasting time and money producing rejected parts and work delays.

Forkardt is familiar with these kinds of projects. We successfully enabled one New England A&D supplier to accurately finish jet engine compressor blisks from a semi-finished form from another facility. This was accomplished by providing a system that effectively adjusted the fixtures lateral runout by means of only two adjusting screws. This specialty solution also accommodated an entire family of collet chucks for flexible production changeover in less than 5 minutes.

Handling Special Materials with Speed and Accuracy

Another challenge of A&D manufacturing is working with specialty materials. Production speed and 100% accuracy can be difficult to achieve when cutting and drilling beta alloys, ceramics, titanium and other materials favored by aerospace engineers in their ongoing quest to reduce weight and material costs. These hard-to-machine substances generate high cutting forces that affect machining accuracy and speed. With proper workholding to support the workpiece, deflection by these cutting forces can be reduced or eliminated, resulting in higher first run yield for your machining operation.

Forkardt – Your Partner for Aerospace Manufacturing

At Forkardt – a Hardinge brand – we understand unique aerospace workholding requirements. We specialize in the design and manufacture of high precision, high quality, specialty and custom designed rotating workholding devices for machine tools. Working with your designers and engineers, we can create customized solutions to the aerospace industry worldwide. Based on your prototype and production requirements, we can develop tooling that enables the machining of components of gas turbine engines and other A&D components with optimal results.

Forkardt’s engineered products have held parts such as turbine blades, blisks, spools, AFT shafts, cones, nozzles, and rotors, for both large and small components manufacturers. Our tooling provides optimal results in the machining of components of the gas turbine engines, including compressor rotors, cones, spools, nozzles and blades. We also produce chucks for general machining and application-specific chucks, cylinders and indexing chucks, expanding mandrels, chucks for hard part turning, collet chucks, steady rests, and grip force meters.