Centres d'usinage verticaux construits selon les normes les plus élevées de l'industrie.

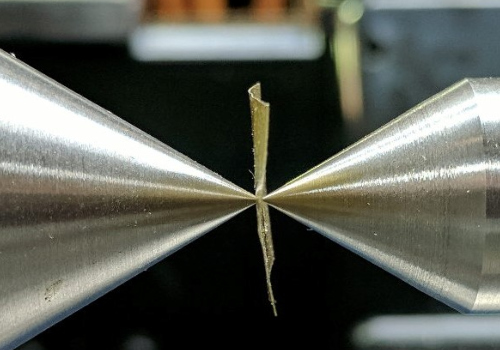

Whether you’re machining simple workpieces, quality molds and dies, or complex prismatic parts, we’ve got just the right Bridgeport XR-Series machining center for your operation. Bridgeport XR machines easily satisfy the most demanding production and precision component machining requirements in the aerospace, automotive, mold and tool making, power engineering and oil / gas sectors, to name a few. When more X-axis travel is needed, then the XR1000 satisfies the requirement nicely. These robust machines offer exceptional stiffness and rigidity to deliver outstanding results in the most demanding production environments. They are particularly wellsuited to machine exotic metals, such as Titanium and Nimonics (nickle-based alloys). To further increase productivity, XR-Series VMCs are configuring for 4-axis machining with an optional interface and rotary table.