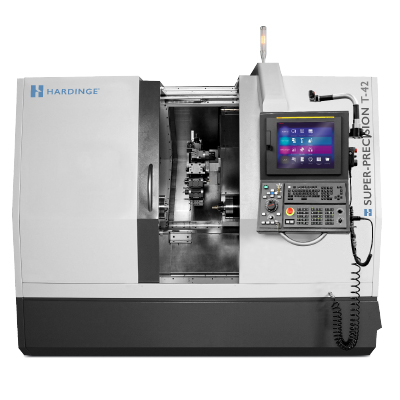

Collet-ready main spindle

The Hardinge collet-ready spindle is the most versatile machine spindle in the industry – it is uniquely designed to accept both collets and jaw chucks without the use of an adaptor. Because the collet seats directly in the spindle, the workpiece is held close to the spindle bearings which provides the ultimate in accuracy, rigidity and gripping force. It also allows for maximum spindle RPMs which increases productivity. This exclusive design also offers numerous workholding capabilities including solid collets, master collets, dead length collets, step chucks, 3-jaw chucks and FlexC collets systems.

Patented interchangeable top plate-standard

Pre-tooled top plates can be quickly interchanged in less than a minute for a new part or family of parts within .0002” repeatability. Once a component operation is set and proven out, the tooled top plate, program, work shift and tool offsets can be removed from the machine and stored until needed for the next batch of similar parts. Repeat jobs can typically save 50% to 80% on setup time over other manufacturer’s gangtype machines. Plus, you can add or remove cutting tools from any location without disturbing any other tools on the top plate. Cut-to-cut time is drastically reduced with gang-tool configuration—there’s no time lost on turret indexing (on the GT27). And you can produce many different parts without changing the top plate tool setup.