Hardinge Kellenberger EMO exhibits from the grinding sector

New VOUMARD 30 grinding machine concept and wide range of new automation solutions

With the new VOUMARD 30 internal grinding machine, Swiss grinding specialist Hardinge Kellenberger has rounded off the high-precision internal grinding expertise of the Voumard brand by adding a machine for all industries whose main focus is on simple internal grinding operations in the small and medium series. The VOUMARD 30 is designed for workpiece lengths up to 150 mm and diameters up to 150 mm. With a footprint of 1.80 x 1.80 m, this very compact machine is particularly interesting for small and medium-sized companies. With its very good price/performance ratio, it is also an ideal entry-level machine. When it comes to equipment, the VOUMARD 30 makes no compromises. Depending on the application, either one or two parallel internal grinding spindles can come into operation. These high-quality internal grinding spindles ensure the best grinding results with short cycle times. They are available with speeds of max. 45,000, up to 120,000 min-1. Other outstanding features are the high-precision work headstock and a high-precision X/Z cross table.

Compact and powerful: VOUMARD 30 for small and medium batch sizes

The machine is equipped with a Fanuc 0i control with the latest BLUE Solution software generation, which is now standard on all Voumard and Kellenberger grinding machines. BLUE Solution is characterized by simple, fast and intuitive touch operation. The operating elements are designed so that they can be quickly grasped and logically selected. The special feature: During data entry, the operator is optimally supported by an intelligent control system. This system is equipped with a plausibility monitor that indicates incorrect entries. The operator can then readjust his entries. For automatic loading, the VOUMARD 30 can be equipped with a robot. The special feature: the robot can be optionally integrated into the machine enclosure.

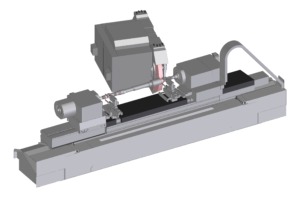

The VOUMARD 1000 internal and external cylindrical grinding machine can be easily automated if required

The high-end internal and external cylindrical grinding machine VOUMARD 1000, already well established in the market, will be shown at the EMO in a new version with a grinding length up to 600 mm and an extended table with the possibility of using a steady rest, ideal for machining long shafts and spindles with high requirements for concentricity.

The kinematically flexible machine design of the VOUMARD 1000 features two linear axes and two rotary axes. The hydrostatic linear axes with newly developed HYDROLIN® guides are backlash-free for positioning accuracies in the nanometer range. The high-precision hydrostatic B axes additionally perform all necessary movements of the dressing and measuring devices. This flexibility makes a large number of machining variants possible and shortens setup times. The spindle turret on the B1 axis is equipped with a uniquely compact grinding spindle head with flexible internal grinding spindle arrangements for max. four grinding spindles.

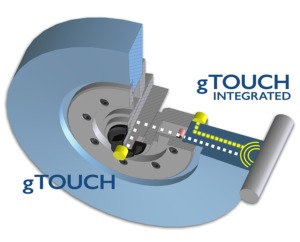

Novelty: Structure-borne sound sensor gTOUCH integrated

The two universal cylindrical grinding machines KELLENBERGER 100 and KELLENBERGER 1000 exhibited at EMO are equipped with many new features for superior grinding results. The KELLENBERGER 100 comes with the innovative gTOUCH integrated structure-borne sound sensor system, a consistent further development of the proven KEL-Touch sensor system, which will in future be known as gTOUCH.

The gTOUCH integrated structure-borne sound sensor was specially developed for the KELLENBERGER 100

The gTOUCH integrated was developed upon the request of Kellenberger and in intensive cooperation with the manufacturer specifically for the design conditions of the KELLENBERGER 100, whose spindle motor is equipped with a direct drive. Noise from the motor can impair the sensitivity of the sensors mounted on the spindle. The new highly sensitive gTOUCH integrated sensor system has as a consequence been integrated into the grinding wheel flange and is now located at the closest point to the source of structure-borne noise, directly on the grinding wheel.

The new flange nut can be used for both old and new flanges. Retrofitting is possible at any time, even on old machines. The gTOUCH integrated sensor system is suitable for use with synchronous and asynchronous motor spindles. The reliable and effective noise shield prevents the passage of background noise, and guarantees highly sensitive signals even on small grinding sections, such as shoulders or phases. The gTOUCH integrated is particularly suitable for scratching and/or dressing with special grinding wheels with carbon or plastic bodies.

Wide range of new automation solutions

The Kellenberger product specialists have expanded the existing product portfolio of automation solutions and added the newly developed Automation FLY to the FLEX and STEP automation solutions that have proven themselves on the market.

The KELLENBERGER 100 will be shown at the EMO with this new Automation FLY, which offers the ideal entry into machine automation in the basic segment with its compact, modular design.

The KELLENBERGER 100 is perfectly automated with the new FLY automation system for shafts parts

The Automation FLY is designed for shaft parts up to Ø 60 mm, length up to 600 mm and workpiece weights of max. 5 kg in alternating mode (length up to 280 mm) and 10 kg in single part mode. Due to its compact size of 1,200 x 1,400 x 2,200 mm (L x W x H), it can be easily integrated into any production environment.

The KELLENBERGER 100 is available in center widths of 1,000 and 600 mm with center heights of 200/250 mm and is designed for workpiece weights up to 150 kg. High drive power of the grinding wheel ensures high productivity, the new Z-guide for high profile accuracy. The C axis with direct drive brings higher accuracy for non-circular grinding.

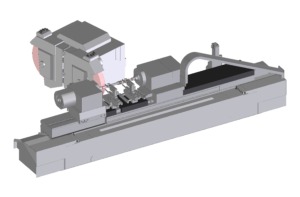

The Kellenberger 1000 has hydrostatic guideways in all main axes for maximum shape accuracy in grinding tasks with interpolating axes. The machine is automated by the Automation FLEX.

The KELLENBERGER 1000 was developed for the high demands of precision manufacturing of prototypes as well as small and medium series, e.g. in tool and die making, the automotive and electrical industry and the aircraft industry. The solid machine table with a reinforced machine bed guarantee very high rigidity and stability, prerequisites for high precision. Workpieces up to 300 kg can be machined.

Over 30 grinding head variants with external and internal grinding spindles are standard on the KELLENBERGER 1000. The optional center heights of 200/250 and 300 mm and center widths of 1,000/1,600 mm expand the machining possibilities considerably and allow a wide range of application-specific configurations. At the EMO, the KELLENBERGER 1000 is shown with the FLEX automation solution, which has proven itself on the market.

Novelty: Integrated Z2 axis for automatic length compensation

Automating grinding processes on workpieces of differing lengths is a challenge. The design engineers at Kellenberger developed an integrated positioning axis (Z2 axis) for this task for the KELLENBERGER 1000, which ensures automatic length compensation during fully automatic loading by a robot or gantry loader. Previously, the workpiece headstock or tailstock had to be repositioned manually for the necessary length compensation during workpiece change. The Z2 axis reduces the changeover time by around 80%.

With the new Z2 axis, the setup time is significantly reduced

The Z2 axis moves on the Z axis. The automatic zero-point shift is performed via a longitudinal probe. Workpieces up to a diameter of 300 mm can be machined. A steady rest can be clamped for longer workpieces. Non-circular parts can also be ground. These are oriented fully automatically on the C-axis.

At the EMO, the Hardinge Group will also be exhibiting the new WEISSER MultiCenter MTS 1200/8 horizontal machining center, two new Bridgeport milling machines and complex ceramic turning on a Hardinge Super Precision T51 lathe. The Forkardt brand, which also belongs to the group, will present solutions from clamping technology.