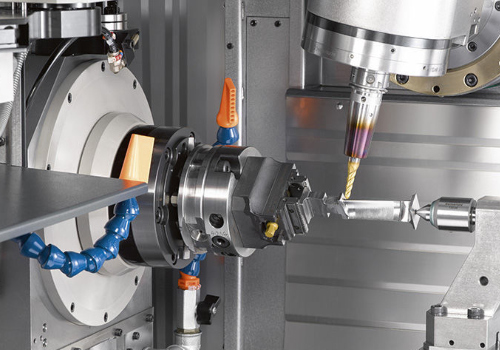

The Bridgeport XT630 5AX 5-Axis CNC machining centers are designed for accuracy, speed and productivity. They are built to provide years of dependable machining on parts requiring consistent tolerances, tough to machine materials and fine surface finishes. The XT630 5AX features a robust traveling beam design on an extremely rigid cast iron base. The Bridgeport XT630 5AX has been designed to stand above all other machines in its class. With a wide range of options to choose from, this makes this 5-axis machine the best in class against competitive machining centers worldwide. Higher end features have been designed into the XT630 5AX machines, while streamlining overall cost to provide a very price competitive machine for the higher end market.