Cutting-edge technology has greatly improved the capabilities of modern machining and metal cutting equipment, enabling it to perform many sophisticated functions. In today’s advanced manufacturing space, customers demand increased customization and shorter lead times, so investing in the latest CNC (Computer Numerical Control) turning, milling, and grinding machines can help manufacturers consistently deliver high quality complex parts with very tight tolerances.

While these advanced machines can deliver tangible benefits – more precise workpieces, faster turnaround, improved productivity, a stronger competitive edge – they can only do so when operating at peak performance. If a machine becomes inoperable or even slows down, it can stop production in its tracks and cost manufacturers thousands of dollars in lost productivity and customer goodwill.

Why Avoid Machine Maintenance?

A haphazard machine maintenance strategy can reduce a company’s overall productive capacity and increase their costs. Complex CNC equipment is designed with the idea that it will be well cared for. Yet, despite the risks, some manufacturers are willing to “play the odds” and postpone the services needed to protect their complex machinery and tools. Whether to save money or avoid shutdowns, these short-sighted views can cause more problems in the long run when the machinery suddenly breaks down and becomes inoperable. Unplanned downtime is nearly always more expensive and disruptive than regularly scheduled preventative maintenance (PM), so why risk it?

Benefits of a PM Plan

Even the most powerful and dependable CNC machinery needs regular servicing and routine care, so it’s wise to adopt a proactive PM strategy. Rather than handling maintenance reactively (after the machine has broken down), commit to a periodic services plan that protects your investment and reduces the risk of equipment failure.

Routine maintenance should be on the minds of everyone who comes in contact with your machines and facility. Supplement your formal PM program with common-sense care of the equipment, including thorough daily cleaning and lubrication of the machinery, replenishing fluids, replacing normal wear items when worn, and responding promptly to equipment’s error messages. A consistent PM checklist can pay big dividends in improved machine reliability, efficiency, and performance.

Preventative Maintenance – How Much is Enough?

How much maintenance will your CNC machine need? That depends on a number of factors, including:

- Number of shifts – Does the CNC machine operate for just one shift, or is it running 24/7? The more it’s used, the more frequently the machine will need servicing.

- Type of materials – Some materials are more abrasive, causing machine components to wear out more quickly, so consider that in your planning.

- Type of work process – Very complex, precise workpieces can tax machinery, which may affect the type and frequency of services needed.

At a minimum, an annual PM evaluation should be performed by your vendor’s service professionals to ensure that the equipment is in tiptop shape – or more often if needed. When your CNC machinery doesn’t seem to be running efficiently, a PM or service call can bring it back to full capacity. Timely service will also help extend equipment life. CNC machinery represents a major investment for your firm, so why not take the steps needed to extend the useful life of these valuable assets?

Create a “Maintenance Mindset”

For a successful maintenance plan, we recommend the following:

- Understand your equipment and its maintenance requirements – Each machine will have acceptable operating conditions, factory recommended service intervals, and prescribed maintenance schedules; this information is included in the Operation Manuals. Be sure your operators read the manuals to familiarize themselves with the equipment’s optimum performance specs, what status messages mean, and appropriate safety procedures.

- Avoid unplanned downtime with PM – Implementing a PM program – as prescribed in the equipment’s documentation — can fix small problems before they become big issues and cause machine downtime. With a consistent PM routine, your CNC machines should run more smoothly and at maximum efficiency, while avoiding disruptions to your production schedule.

- Train your operators – Your operators should know more than just how to start and operate their machinery. They need to be educated on the day-to-day inspection and “housekeeping” tasks required by their particular machine, then perform those tasks faithfully. Also, trained operators can be your “eyes and ears” on the floor. A keen-eyed worker can sense when something is amiss with a machine’s operations, identifying problems early before they cause damage.

- Keep Spare Parts on Hand – Even with a regular maintenance schedule, the inevitable will happen and a part will fail. Repairing CNC equipment will take a lot longer if you have to wait for replacement parts, disrupting operations and affecting deadlines. However, with an inventory of common spare parts on hand, you can replace components more quickly and minimize downtime.

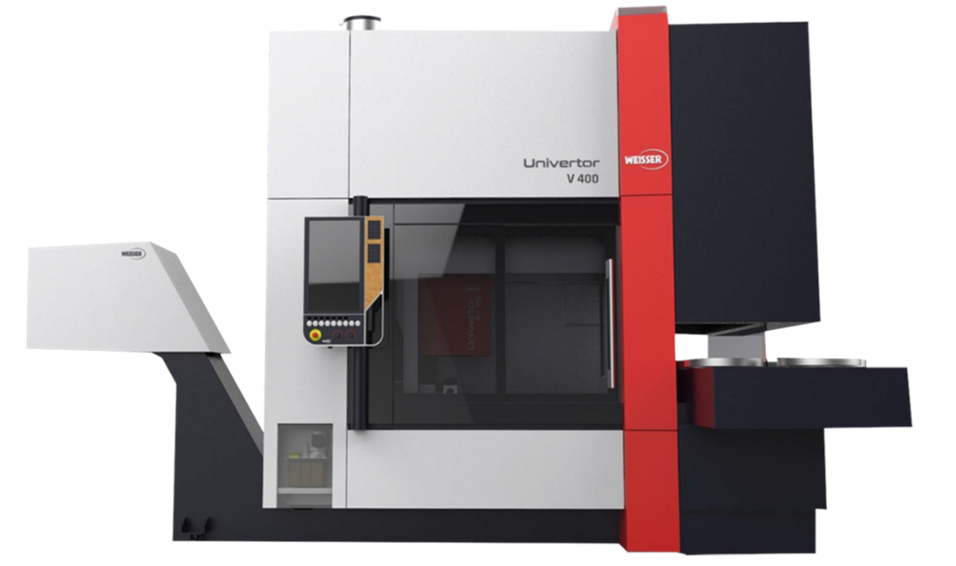

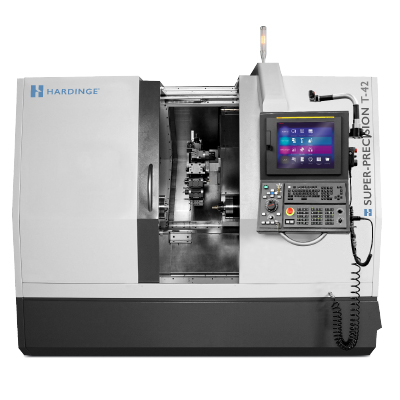

Hardinge

As a leading international provider of advanced metal-cutting solutions, Hardinge is committed to customers’ success with our equipment. To enhance the performance of our machinery and resolve customer issues, we offer a variety of technical service programs performed by highly trained technicians. For example, our Technical Support help desk is staffed by field-trained service professionals who can quickly and accurately answer customer questions. We also offer a range of support services, including equipment health check-ups, off- and on-site operator training, spare parts inventory, and machine refurbishments – all designed to ensure your machine investment is protected.