Quantum leap in accuracy

Author: Andrea Jäger (text and photos)

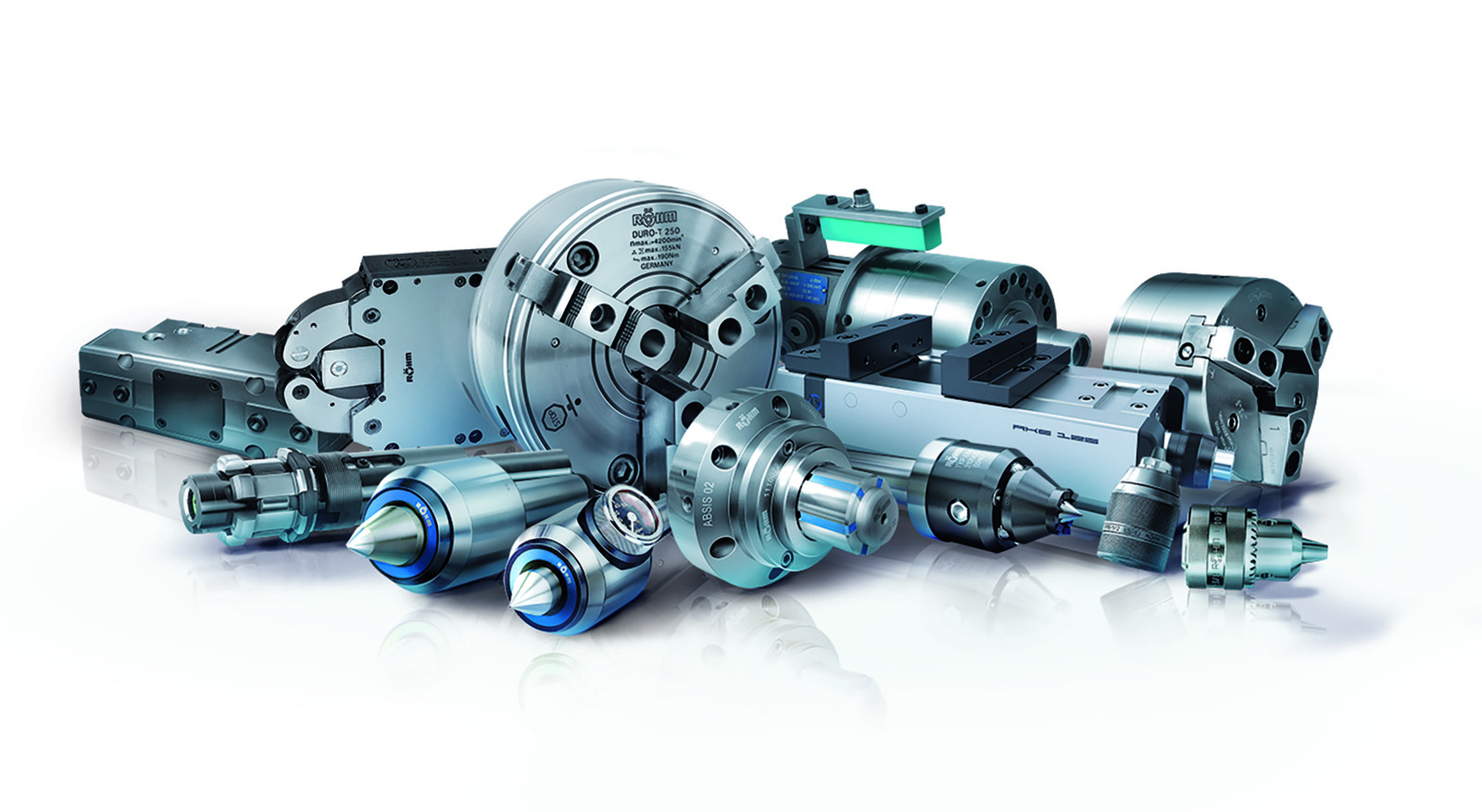

Röhm GmbH looks back on a history of more than 100 years as a manufacturer of tool and workpiece clamping systems. During these years the company has grown steadily and today serves international markets with three production facilitites in Germany and 1,300 employees worldwide. At the main German plant in Sontheim/Brenz, 750 employees primarily manufacture technology-oriented system solutions for sectors such as the automotive industry, mechanical engineering, aerospace and many others on 41,000 square meters. The parts in question are finished on Kellenberger Premium grinding machines.

Of all things, it was an internal crisis which brought a decline in sales, taking Röhm to the abyss for the first time in the company’s long history. After several difficult years, the acquisition of the company by Austrian investor Helmut Rothenberger Group in September 2017 brought the return to calmer waters. Member of the group Gerhard Glanz took over both as CEO and co-partner at Röhm. In his view, the company’s portfolio fitted perfectly with the existing business areas of the Rothenberger Holding, which generates a sales volume of 1.3 billion euros with over 100 operating companies, many of them in the machine tools sector.

Applying an extensive restructuring project, Glanz achieved the “turnaround“ within a few months. He restored confidence both among employees and customers and brought Röhm back into the profit zone. In order to make the company fit for the future, an investment sum of several million euros was made available, which flowed in new machinery and systems. The aim for the future was to produce Röhm‘s high-tech products in even better quality and at the same time more cost-effectively.

“Made in Germany” paired with “Swiss Made”

For division manager Alexander Scheitenberger and his 35 staff members the investment came exactly at the right time. Scheitenberger‘s department manufactures tool clamping systems, 40% of which are customised special designs. A trained industrial mechanic, Scheitenberger has been with Röhm since 1990 and is very familiar with all machining processes and the Röhm portfolio, which includes drill chucks, center punches, lathe chucks and vises, robot gripping technology, power chucks, clamping cylinders, mandrels, and tool clamping systems.

Division manager Alexander Scheitenberger (to the right) and Erhard Bader,

head of production, are very satisfied with the decision for the K100

The parts were being machined on a KEL-VARIA universal grinding machine with center width 1,000 mm, which had been in use for 18 years. Now spare parts for key components were no longer available, making a replacement investment unavoidable. Scheitenberger and head of production Erhard Bader agreed, that the new machine should again be a Kellenberger. „We have had very good experience with the KEL-VARIA. The reliability, accuracy, and process safety of the machine over the runtime were outstanding. In addition, the cooperation with Kellenberger has always been characterized by a high level of professionalism. Erich Ziegler, the Kellenberger area manager who is responsible for us gave us excellent advice on the new procurement.” Since 2018, the Kellenberger product portfolio has offered two machine designs, which can meet the machining tasks at Röhm. The new KELLENBERGER 100 platform concept proved to be the best solution, especially since Swiss manufacturer Wenger had specially adapted an automation to the machine.

Versatile platform solution

The task assigned to the engineers in Goldach, Switzerland, in regard to the KELLENBERGER 100 was to develop a platform on which different machine concepts could be realised with a strong customer orientation. The segment of high-performance, low-cost grinding machines within the group was integrated into the concept. The modular solution on a common platform and a new assembly concept to reduce throughput time enable cost-efficient production of the machine and thus a very good price/performance ratio. The machine concept was optimised in close cooperation with the service department. This resulted in speeding up maintenance and service processes and better accessibility to maintenance-intensive components.

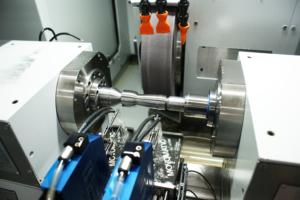

Machining with RÖHM high-precision centers on the Kellenberger 100

The Kellenberger 100 offers the widest range of standard configurations for a great variety of grinding operations. The machine is available in center widths 1,000/600 mm und center height 200 mm, and is designed for part weights of up to 150 kg. A higher drive power for the grinding wheel (11,5 kW) ensures increased productivity, while the newly-designed guide in the Z axis brings greater profile accuracy. For higher accuracy in non-circular grinding, the C axis is equipped with a direct drive. Röhm opted for a machine with a center width of 1,000 mm.

The K100 has a compact, collision-free tandem grinding head with motor spindles. 10 grinding head variants are available for optimised design of the machine in relation to the machined parts. The reinforced casing allows the largest grinding wheel diameters for internal grinding (up to 125 mm).

The user-friendly, ergonomic design of the KELLENBERGER 100 machines is complemented by intuitive operator guidance via touch screen interface. The machines are equipped with a state-of-the-art Fanuc 31i CNC control with 19″ touch screen. Various ready-made software packages are included as standard or can be added as an option. They cover simple workpieces, complex workpieces in the shortest machining time, and complex contours and profiles.

Smart loading solution

The Kellenberger 100 is ideal for a wide variety of automation solutions. Swiss automation specialist Wenger has custom-designed the loading solution WeFlex for chucks and shaft parts especially for the K100. The WeFlex loader enables automated processing of shaft parts Ø 6 – 100 mm, L = 20-600 mm, max. gripper diameter = 80 mm and chuck parts Ø 4-100 mm, L = 15-100 mm, max. gripper diameter = 80 mm with workpiece weights of max. 5 kg in alternating mode, max. 15 kg in single part mode. Interchangeable gripper heads facilitate quick changeover between shaft and chuck parts. In the stacking module, 8 pallet spaces of size 400 x 600 mm are available. Inserts for shaft or chuck parts can be inserted in the pallet frames. An ideal solution for Erhard Bader and Alexander Scheitenberger.

Interior of the WeFlex loader with line gantry and pallet changer

The machine is loaded via telescopic line gantry. An automatic hatch closes off the machine room during machining to ensure the thermal stability of the machine. Directly at the infeed, electricity and compressed air are recorded, which allows the energy consumption of the WeFlex to be recorded and visualized. To reduce energy consumption, the speed of the WeFlex is automatically adjusted to the cycle time of the processing machine. An image-guided setup wizard assists the operator when changing over to a new workpiece. Wenger managing director Michael Wenger supervised the initial commissioning, which was followed by a training for the Röhm employees at Kellenberger. One week after machine commissioning, 3-shift operation was resumed. “The reliability of the loader works is very high,“ reports Alexander Scheitenberger. “We haven’t had any downtimes so far.”

Expectations far exceeded

The service package also includes remote maintenance of the machine. Plus: minor service work is handled internally at Röhm. “A couple of our employees have undergone service training at Kellenberger with a focus on the new machine, so they can carry out minor repairs themselves,“ says Scheitenberger. “There is no need to call the Kellenberger service team for a minor issue. But if you do need the service, it’s fast and reliable.“

The conclusions of Alexander Scheitenberger and his colleagues are very positive: „In terms of accuracy the new machine has brought us a quantum leap. Today, we grind with an accuracy of 2 micro meters with process reliability. The surface quality of the machined tool clamp is so good that, with the same polishing times, the results are many times better, from Ra 0.3-0.4 micro meters to below Ra 0,1,“ and he adds with satisfaction: „Due to the larger grinding wheel and because the new machine is simply faster than the old one, we have 25% increase in productivity. In addition, personnel costs are 30% lower, because, due to automation, one operator is sufficient for two machines.“ It doesn’t get any better than that!

Metal cutting mechanic Andreas Oszfolk knows his way around grinding. He operates two Kellenberger machines, including the K100 with automation.

i USER

Röhm GmbH D-89567 Sontheim/Brenz

Phone : + 49 7325 16-0

i MANUFACTURER

HARDINGE/L. KELLENBERGER & Co. Thannäckerstrasse 22, 9403 Goldach, Switzerland

Phone : +41 71 242 91 11

Andrea Jäger is a freelance specialist journalist in Murrhardt, Germany.

jaeger@diejaegerin-wv.de